3:23:24 PM | 9/20/2019

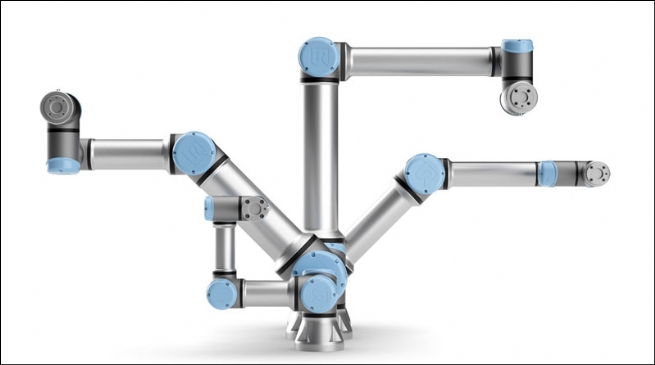

Universal Robots (UR), the most trusted and widely-deployed collaborative robot (cobot) manufacturer in the world, on September 17 announced the immediate availability of the UR16e which boasts an impressive 16 kg payload capability.

UR16e combines the high payload with an arm reach of 900 mm and has a pose repeatability, the ability to precisely reproduce the same desired poses or positions, on repeat, of +/- 0.05 mm. This makes it ideal for automating tasks such as heavy-duty material handling, heavy-part handling, and machine tending.

“In today’s uncertain economic climate manufacturers need to look at flexible solutions to stay competitive,” said Jürgen von Hollen, President of Universal Robots. “With UR16e, we meet the need for a collaborative robot that can tackle heavy-duty tasks reliably and efficiently. This launch significantly expands the versatility of our product portfolio and gives manufacturers even more ways to improve performance, overcome labor challenges, and grow their business.”

Developed on UR’s innovative e-Series platform, the UR16e offers immense benefits, capabilities and value for manufacturers, including fast and frictionless deployment with easy programming and a small footprint, addresses ergonomic challenges while lowering cost, and ideal for heavy-duty material handling and machine tending.

“At Universal Robots we continue to push the boundaries of what’s possible with collaborative automation,” continued von Hollen. “Today, we’re making it easier than ever for every manufacturer to capitalise on the power of automation by bringing a cobot to market that is built to do more as it delivers more payload than our other cobots.”

Like with UR’s other e-Series cobots; UR3e, UR5e and UR10e, the UR16e includes built-in force sensing, 17 configurable safety functions, including customisable stopping time and stopping distance, and an intuitive programming flow. UR16e meets the most demanding compliance regulations and safety standards for unobstructed human-robot collaboration, including EN ISO 13849-1, PLd, Category 3, and full EN ISO 10218-1.

Southeast Asian countries significantly outperform the rest of the world in robot adoption while Europe and the United States (US) lag behind. This includes Vietnam, which ranked the seventh largest robot market globally in 2017. The country’s robot sales soared from about 1,600 units in 2016 to almost 8,300 units the next year driven by the electrical/electronic industry. Vietnam is the second largest electronics exporter in ASEAN.

The Vietnamese government unveiled the ‘Made in Vietnam 4.0 Program’ to prepare the country to be at the forefront of Industry 4.0. The programme promotes the development of new industries, policies, mindset and technology towards Industry 4.0 and the country’s digital economy ambitions.

James McKew, Regional Director of APAC at Universal Robots, said: “We see greater awareness of robotic solutions and cobots in particular in Southeast Asia. The region is very attractive to companies – domestic or international - looking to increase their competitive edge, and whether setting up new facilities, or relocating from other countries. The new UR16e expands the capabilities of our e-Series range, catering to a wider range of business needs.”

Linh Phan