10:02:37 AM | 9/3/2025

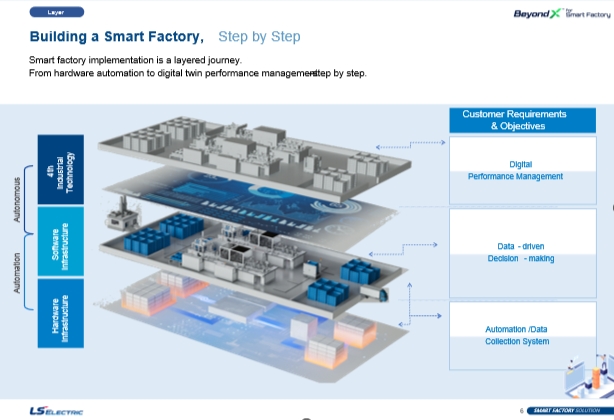

In the era of digital transformation, the smart factory is emerging as a key driver of competitiveness and progress toward sustainable development. While automation was once regarded as the height of manufacturing innovation, smart factories advance further by fully integrating digital technologies, big data, artificial intelligence (AI), and the Internet of Things (IoT). This model not only streamlines processes but also enhances quality, conserves energy, and lowers costs for enterprises.

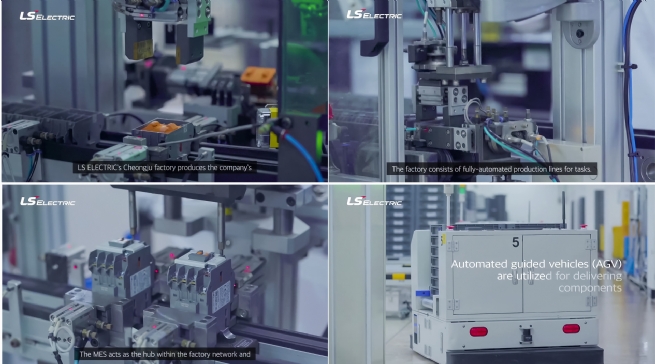

A leading example is LS ELECTRIC’s Cheongju plant in South Korea, where the most advanced technologies have been implemented to build a fully intelligent manufacturing environment that serves as a benchmark for the global Industry 4.0 trend.

Comprehensive digital twin - the “heart” of the smart factory

A smart factory is understood as a modern production environment where advanced technologies operate in synchronization. IoT connects devices and sensors to collect real-time data; AI analyzes, predicts, and optimizes processes; digital twin creates a virtual replica of the entire plant; while big data and cloud computing process and store massive volumes of data to support fast and accurate decision-making.

At Cheongju, LS ELECTRIC has deployed a digital twin that simulates the entire factory in real time. Indicators such as line speed, equipment performance, energy consumption, and product quality are automatically collected through IoT and PLC systems, then integrated into IT platforms such as MES (Manufacturing Execution System), ERP (Enterprise Resource Planning), and QMS (Quality Management System) for monitoring and instant feedback. On a 3D screen, the digital replica accurately reflects the state of machinery, worker positions, material flows, and continuously updates KPI metrics.

Crucially, the system goes beyond visualization by connecting with AI models to automatically identify root causes of defects, analyze equipment utilization rates, and propose improvements, thereby increasing productivity and reducing risks. This is the heart that allows the smart factory to function like a living organism, continuously self-optimizing and evolving.

The LS ELECTRIC Cheongju plant incorporates numerous backbone technologies now defining “smart” factories: IoT-based automation for intelligent production lines; autonomous robots for inventory handling; real-time AI-based automated welding; and systems for monitoring vibration and noise through signal interference analysis.

Comprehensive solution ecosystem from LS ELECTRIC

What sets LS ELECTRIC apart is its development of a comprehensive and customizable solution ecosystem tailored to the needs of each enterprise, built on two main pillars of production management and energy management.

In production management, MES plays a central role by optimizing operations and standardizing processes to international benchmarks, SCM manages the entire supply chain from planning and procurement to inventory optimization, QMS provides full quality management ensuring traceability, compliance with global standards, and continuous improvement, SAM (Smart Asset Management) enables intelligent asset management predicting and preventing equipment failures, RMS (Recipe Management System) manages production formulas reducing deviations and improving precision, and digital warehouse management enhances inventory accuracy and optimizes logistics.

In energy management, LS ELECTRIC has developed FEMS (Factory Energy Management System) which monitors and optimizes energy use in real time while helping enterprises implement ESG strategies, MEMS (Manufacturing Energy Management System) integrates production and energy data to analyze consumption efficiency at every stage and recommends ways to save electricity and cut carbon emissions, allowing businesses to gain both economic benefits and meet strict sustainability requirements.

If IoT is considered the senses, then AI is the brain of the smart factory, and LS ELECTRIC applies AI across multiple critical stages including product quality inspection through machine vision, defect analysis and root cause identification, and automated process improvement proposals, with AMR robots integrated with AI coordinating intelligent material handling to shorten delivery times and accelerate production lines.

From vision to sustainable manufacturing practices

To demonstrate its capabilities, LS ELECTRIC has produced a series of videos documenting its smart factory journey since 2016, featuring 24/7 monitoring with digital twin, real-time dispatching optimization, and AI-driven quality inspection and defect analysis. This reflects a clear roadmap: from IT infrastructure development and real-time data collection, to building autonomous factories and advancing toward a global production model.

The smart factory is no longer just a technology trend but a practical solution to the challenges of competitiveness and sustainability. The integration of AI, IoT, big data, and real-time management has created a “zero-defect” production environment that saves energy, reduces costs, and improves product quality.

At the Yen Phong Industrial Park in Vietnam, LS ELECTRIC has introduced the country’s first intelligent energy management system, integrating rooftop solar panels and energy storage solutions. This smart system coordinates control across grid electricity, solar power, battery storage, and automated lighting to achieve optimal efficiency.

With its strategic vision, LS ELECTRIC is strengthening its pioneering role in smart manufacturing. The company has achieved success in South Korea and is extending the model to other markets, including Vietnam, where digital transformation and competitiveness are urgent priorities.

In the future, the smart factory will not merely be a tool for improving efficiency but will become a foundation for Vietnamese enterprises to achieve sustainable growth, comply with stringent global standards, and contribute significantly to carbon reduction and environmental protection.

Nguyen Bach (Vietnam Business Forum)