10:54:54 AM | 9/9/2025

Vietnam’s manufacturing industry is standing at a pivotal crossroads. While exports reach tens of billions of U.S. dollars annually, the sector remains overly dependent on contract processing, with weak supply chain linkages and modest added value. As global supply chains continue to shift, the pressure to strengthen domestic enterprises has never been more urgent.

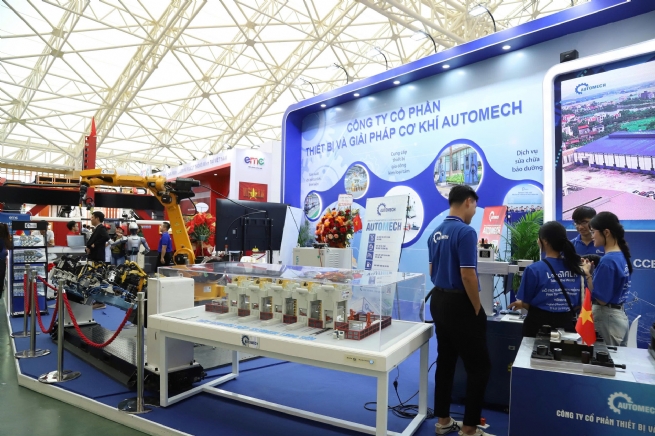

In this context, the FBC ASEAN 2025 – Manufacturing Business Convention, set for mid-September at the VIETNAM EXPOSITION CENTER in Hanoi, promises to deliver a strong boost. Co-hosted by NC Network Vietnam and the Vietnam Association for Supporting Industries (VASI), the event will feature more than 500 booths from local and international enterprises across Germany, Italy, Japan, Thailand, and beyond. Through multiple platforms, participants will also gain access to a global network of more than 23,000 manufacturers. Notably, 80% of exhibitors are direct producers—underscoring the event’s practical focus. Beyond product showcases, the convention will connect Vietnamese enterprises with over 50 global buyers such as Mitsubishi Electric, Panasonic, Samsung, Fujifilm, Tiger, Foster, and Sanyo Denki.

Bridging opportunities for global supply chain integration

According to the Ministry of Industry and Trade (MoIT), Vietnam’s manufacturing and supporting industries currently contribute around 16–17% of national GDP and provide millions of jobs. Yet localization remains limited, averaging just 30–35% in most sectors—well below Thailand and China. Key barriers include restricted production capacity, underinvestment in technology renewal, and limited managerial and R&D expertise among domestic enterprises.

FBC ASEAN 2025 is therefore designed not only as a showcase of advanced machinery, automation, and electrical–electronic components but also as a strategic platform to bridge Vietnamese enterprises with international supply chains. Alongside the exhibition, participants will engage in specialized seminars on cooperation and technology transfer, as well as leverage the J-TECH online showroom to pre-schedule meetings with potential partners.

“This model enhances efficiency, turning the exhibition into a launchpad for sustainable partnerships rather than a short-lived networking event,” a MoIT representative emphasized.

Industry insiders also underline the critical role of associations in this process. Mr. Phan Dang Tuan, Chairman of VASI, affirmed:

“The Association is not a bystander but an active player, which is why we are directly involved in organizing the event. The biggest challenge for Vietnam’s manufacturing industry remains market access. For global buyers, VASI’s presence is essential. Exhibitions like FBC ASEAN 2025 enable us to connect enterprises, identify products that domestic firms can supply, and ensure Vietnamese manufacturers gain visibility in the global value chain.”

Driving Vietnam’s transition from OEM to ODM – Industry perspectives

Industry leaders agree that focused investment is essential for Vietnam to move up the value chain. Mr. Chu Viet Cuong, Director of the Industrial Development Support Center (IDC) under the MoIT’s Industry Agency, observed that while Vietnam has over 6,000 domestic supporting industry enterprises, they still fail to meet local demand for parts and components. Localization rates remain modest: 15–20% in machinery and 5–20% in automotive.

“Vietnam must concentrate on priority sectors such as mechanical engineering, automotive, electronics, semiconductors, and textiles–footwear,” Mr. Cuong stated. “Equally important is encouraging technology transfer from foreign-invested enterprises to local firms through mechanisms that require localization and supply chain linkages.”

Experts further note that Vietnam’s domestic market of 100 million consumers should be treated as a proving ground. By meeting rising standards for quality, sustainability, and environmental compliance at home, enterprises will gain the confidence and credibility to expand globally.

This perspective is shared by foreign investors. Mr. Ogawa Tsuyoshi, General Director of TKR Manufacturing Vietnam Co., Ltd.—a 100% Japanese-invested enterprise with more than 500 employees in Vietnam—explained:

“This year marks the first time TKR will present a booth at FBC ASEAN. Previously, we participated mainly to source suppliers. Now, we want to use this platform to showcase our products and demonstrate how TKR can meet customer needs, not only in northern Vietnam but also among international partners.”

In this regard, FBC ASEAN 2025 offers dual benefits: expanding international cooperation while pushing Vietnamese firms to innovate and strengthen capabilities. The exhibition could mark a turning point, helping the sector evolve from being merely a “processing workshop” to becoming a trusted production partner integrated into global supply chains.

With strong international participation and an emphasis on practical cooperation, FBC ASEAN 2025 is set to play a crucial role in accelerating Vietnam’s industrial upgrade. For domestic enterprises, the event presents both a challenge and an opportunity: to innovate, integrate, and position themselves as reliable partners in the global supply chain.

LA (Vietnam Business Forum)